Hubei Kirin Industry And Trade Co., Ltd

ABOUT US

Kirin Industries excel in the areas of manufacturing and supply chain management, as deeply involved, and invested in tomato products manufacturing in China, making us a one-stop solution for all things tomato-related to our clients. Our key employees have deep expertise and years of experience in the industry and are committed to staying at the forefront of trends and innovation.

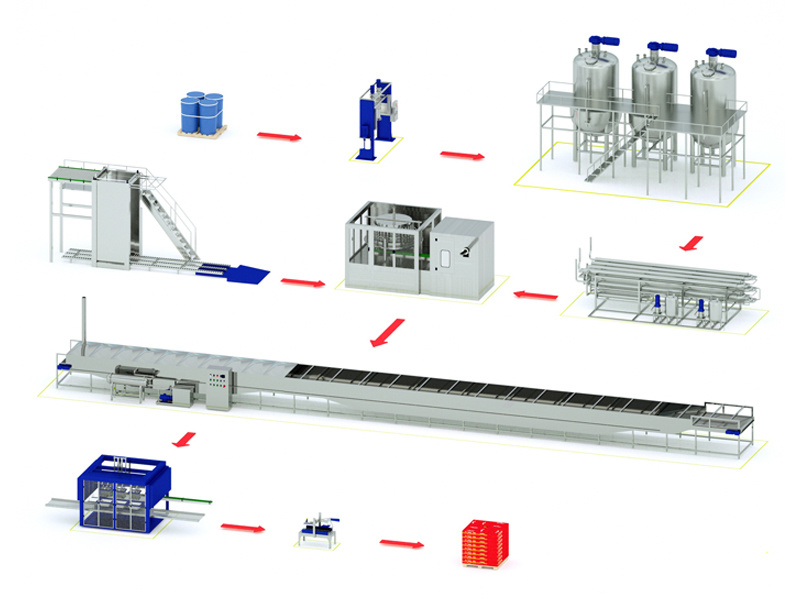

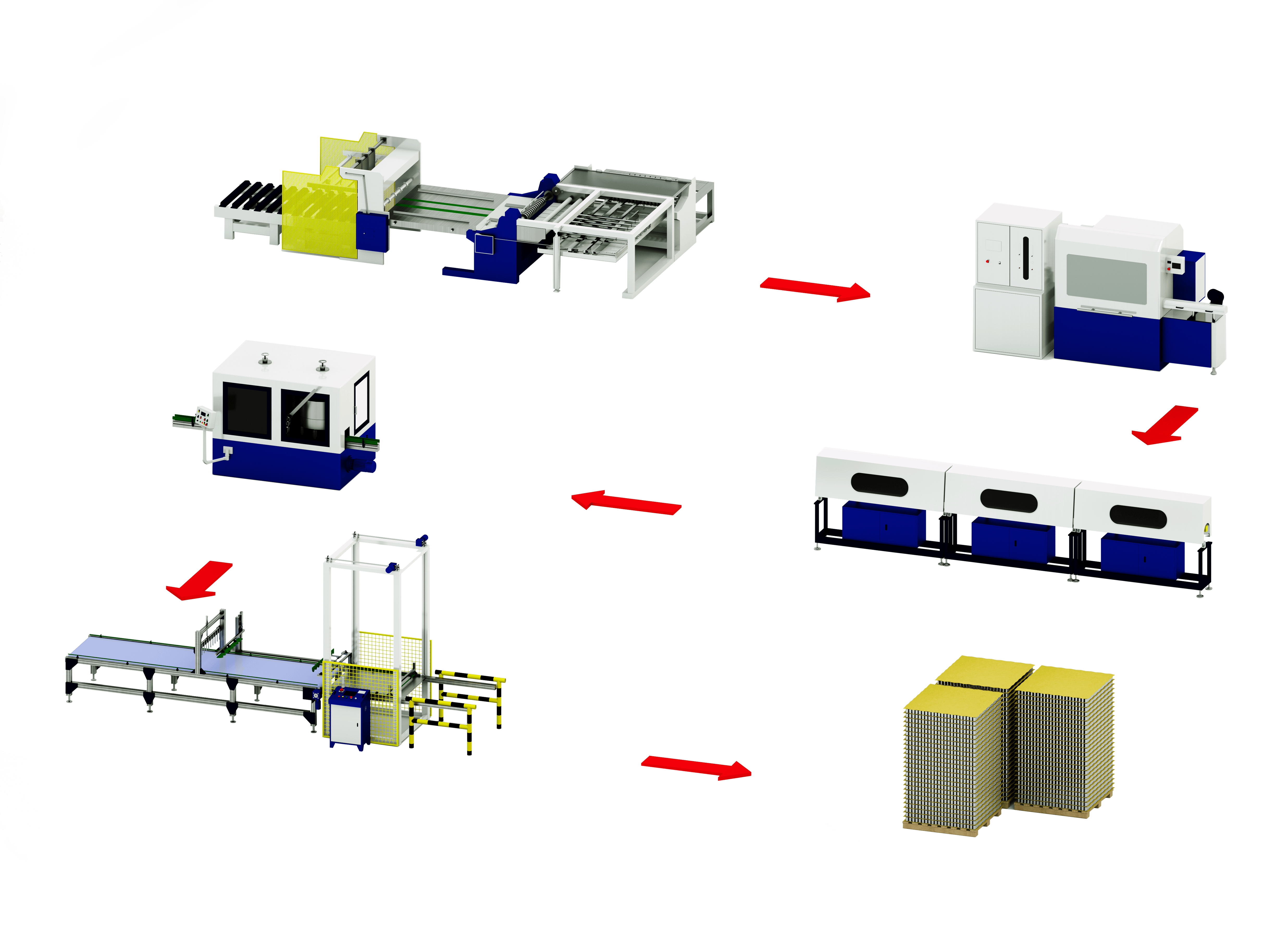

Our offerings range from tomato products retail pack, customized production line manufacturing and supply chain management to sourcing and supplying raw materials and packaging, and even developing production recipes. Our team of professionals is dedicated to providing our clients with our wealth of experience and knowledge, adding value to every interaction.